Products

Precision Machined Products

Precision Machined Products

A Comprehensive guide about precision machining component

Have you ever thought about how these big engines and aluminum parts are being made? This is where these precision machinings are being used. The common use of a machine part is to precisely cut a specific area of a material. We use these machined parts in our everyday life. These machine parts go through a process in which they are cut into a specific shape depending upon the requirement.

For designing and developing machines, tools, parts, and other precise technical manufacturing, precision machining is being used. Using the Precision machining component, we can control the process under strict requirements and help manage tolerance. If you buy these machining components, then you can get these from Imperial World Trade Pvt. Ltd., which is a very good deal.

Why should you use our machined parts ?

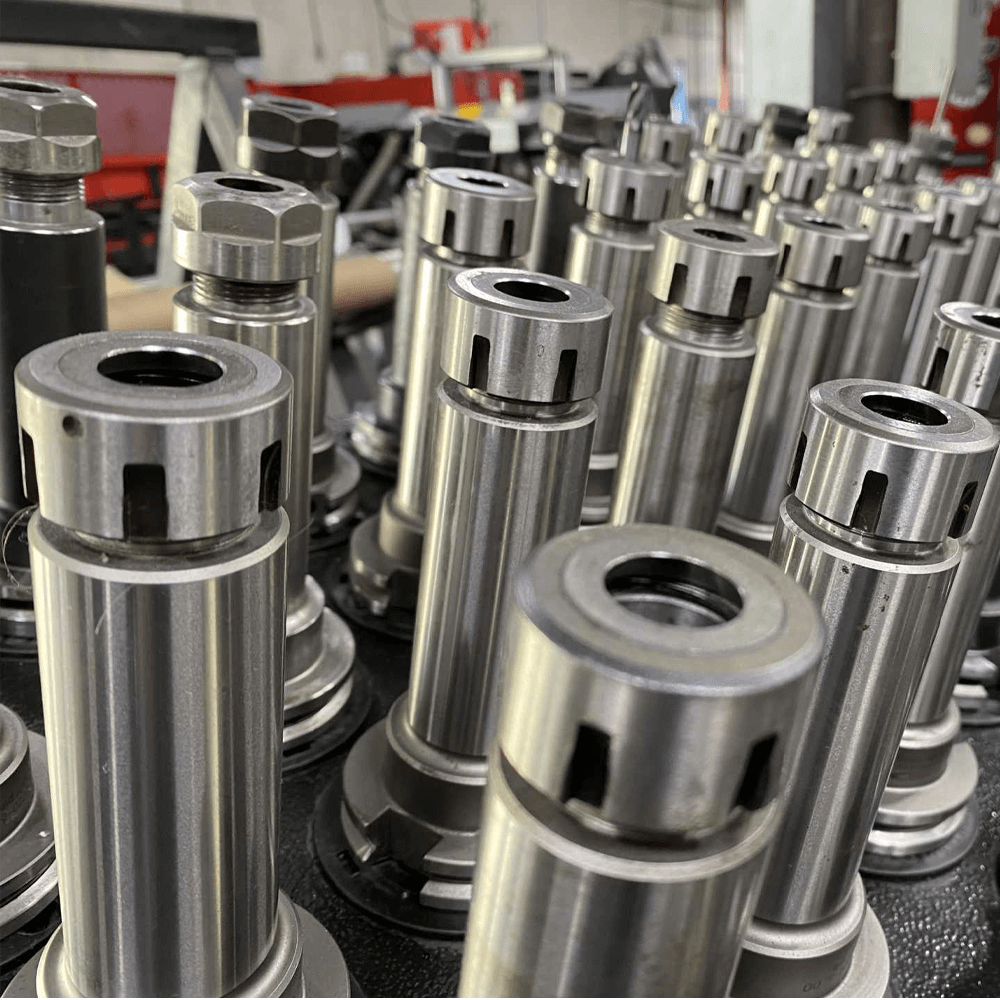

Many professionals, R&D departments, Product designers, and companies use our machining parts for precision cutting. Our machine is durable and strong to use as it is made of solid metals and other strong materials. We have various types of machinery in various shapes, sizes, designs, and thicknesses.

You also work with different companies, as our precision machined parts are tried and tested for all types of industrial manufacturing processes. Our products meet industry standards and are verified with industry-level certification. Other than this, our machined parts have many advantages:

Design Freedom

Finishing the product

By using the Precision machining component, we avoid the quality issue of the surface as in molding like jetting, flow lines and flash at the parting line. In terms of finishing on the surface, we achieved a very good standard by doing some precise work and moderate post-processing.

In 3d printing, you can have a better surface finish without even post-processing. In 3d printing or FDM printing, there could be a line or visible layer on the surface, which some chemical treatment or simple sanding can smoothen, but in machining parts, there are no such visible lines or layers.

Strength

Alternations

Quality

Good for prototype

The procedure of precision machine component

- The first step of precision machining starts with CAD software to sketch the design on the computer.

- Then, the engineer makes a 3D diagram of the sketch by using software like AutoCAD to execute the design.

- Using CAM programs, we put these in computer-based CNC machines to develop precise parts, and the computer program machines remove the raw material.

- These processes of precision machining are the most accurate. According to the computer software's instructions, every cut is done by the CNC machine.

- We use the machine to minimize the error done by the human as the machine can do all the cutting with lesser error. With tolerances of 0.05 mm to 0.01 mm, we can repeatedly generate hundreds of the same parts without even a minor error.

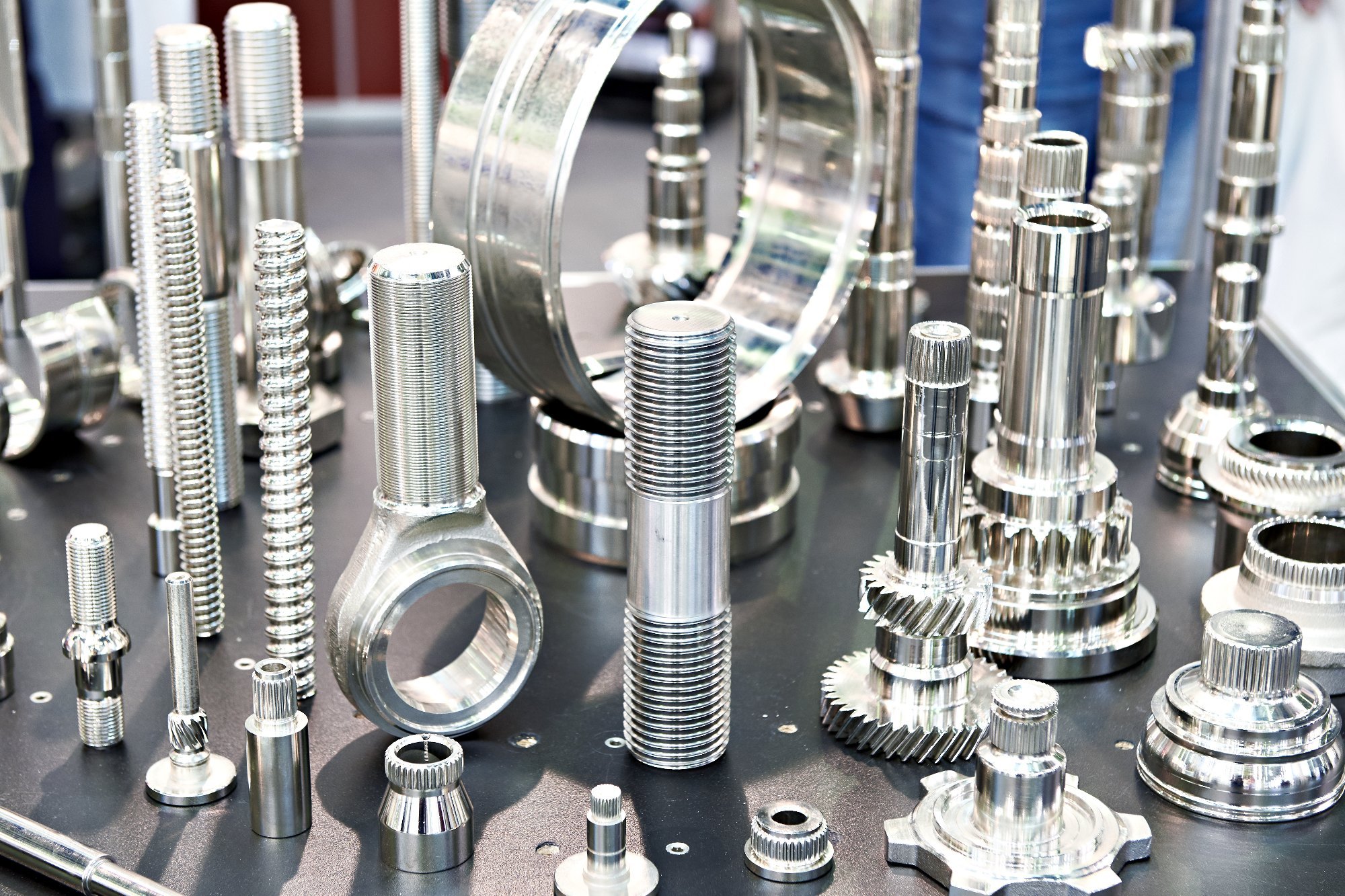

Precision machining and CNC machining are one of the most crucial parts of component construction. The term CNC machine refers to computer numerical control in a variety of applications of machine applications known for programmable machine features. So the Precision Machined Components are called CNC machining as a controlled machine fabricates them. We provide these machining and application of our product to different industries like firearms, hydraulis, gas and oil, aerospace and medical, etc.

Some different types of CNC machining

- Turning machines and CNC lathes

- CNC machines for milling

- Laser CNC machine

- Electric discharge machine

- Plasma cutting CNC machine

- Waterjet cutting CNC machine

- CNC grinder

We have various machined parts of different materials, such as plastic and metals. It is very difficult to cut or penetrate any hard material. That’s why some materials are a bit more difficult to make a machine than others. If you use too many cutting tools and try to penetrate the metal, it will vibrate more, and the material’s quality will decrease. And the material with a low melting point and soft material might deform and make contact with the cutting tool.