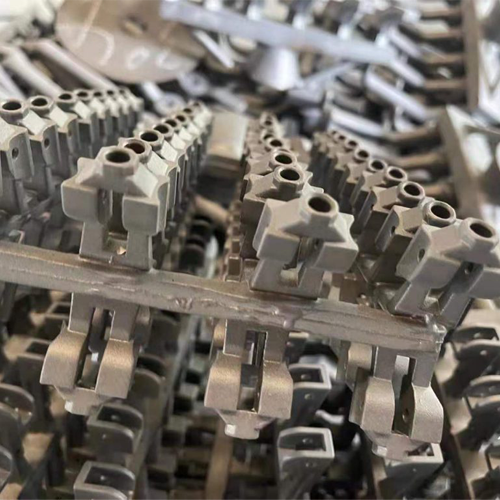

Casting Products & Parts

Aluminum Pressure Die Casting

Aluminum Die Casting

Aluminum Pressure Die Casting

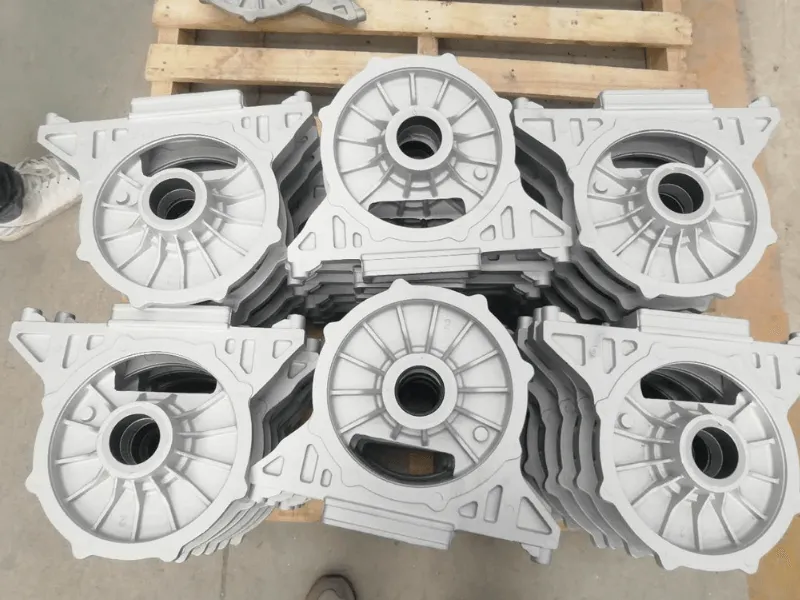

Aluminum dies casting is considered a non-expendable technique that can be repeatedly used to produce different shapes, sizes, and thicknesses of aluminum alloys for die casting. The aluminum die-casting process also assembles lightweight parts, sustains high operating temperatures, and provides superior corrosion opposition for diverse industrial applications.

Aluminum high-pressure die casting is a process in which aluminum is injected into the machine under high pressure to convert it into a mold crater or die to assemble products and elements. Compared to other casting processes, High pressure dies casting process is high in speed, producing parts in high volume and inexpensive.

Aluminum Die Casting

Process Of Aluminum Die Casting!

The casting process executes a steel mold, often delivering castings immediately. The die must be created in at least two units to allow castings deduction. The casting cycle starts with the two die halves being connected tightly together by the die-casting press. Molten aluminum is implanted into the die cavity, where it solidifies quickly. These sections are mounted securely in a device and are placed so that one is fixed while the other is moveable. The die halves are pulled apart, and the casting is expelled. Die casting dies can be easy or complex, having moveable drops, cores, or other units depending on the sophistication of the casting. Most devices use mechanisms actuated by hydraulic cylinders to perform locking. Others use direct-acting hydraulic force. Large or small die-casting appliances are absolute only in injecting molten metal into the die.

Application Of Aluminum Pressure Die Casting!

There are many applications of ALUMINUM Pressure DIE CASTING, but here we will discuss the top five industries where it is applied.

Aerospace

Agriculture Sector

Automotive Industry

Industrial equipment

Medical Industry

Aluminum Pressure Die Casting

The Reason That Makes Aluminum Pressure Die Casting The Most Popular In The Manufacturing Process!

The most popular and widely used process to manufacture lightweight, complex, high-strength, & economic parts. Most OEMs find replacing parts manufactured with standard materials & processes with aluminum die casting profitable & operationally exceptional.

High-pressure die casting is the most widely acknowledged process for producing parts in the electrical, automotive, surgical, consumer goods, aerospace, electric vehicles industries and medical. This is primarily due to its excellent quality, easy procurement & timely delivery, and aluminum dies casting finds its application almost in every industry.

Aluminum is the most widely used metal in the manufacturing of die castings. The cost-effectiveness of aluminum, combined with its good corrosion resistance, makes it the metal of choice for most die-casting products.

Many other reasons exist for the preference for aluminum alloys in the die-casting process. First of all, aluminum is easy to cast. It is lightweight, soft, and malleable, has excellent machining abilities and has a low melting point. These qualities make it very easy to pour molten aluminum into a mold. Aluminum is also cheap and is abundantly available, along with excellent recyclability.

Bullet points to consider aluminum as the best metal:

- It offers superior strength & hardness

- Aluminium is lightweight

- It's easy to cast

- It has a low melting point

- It is ductile

- It is soft

- It offers superior strength & hardness

- It offers excellent machining capabilities

- It provides excellent recycling capabilities

- It is corrosion resistant

- It has an excellent thermal conductivity

- It has high electrical conductivity

Conclusion

As the best Aluminum High pressure Die Castings parts manufacturer, we always provide well-tested and trusted High-pressure Die Castings parts to customers; get connected today with the leading manufacturer and exporter at Imperial World Trade PVT. We are highly experienced and skilled in supplying Foundry Materials, Industrial Filter Bags, Cast Iron Powders, and Steel and Iron castings.