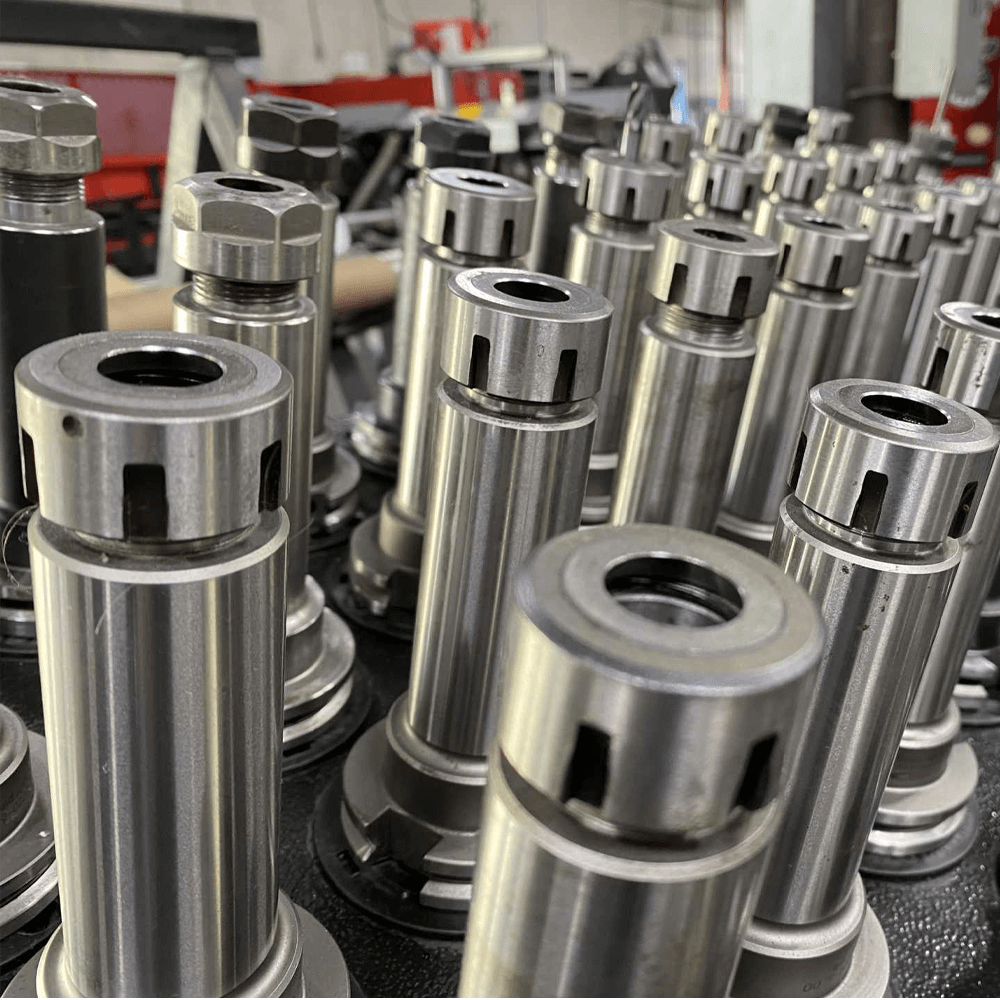

Precision Machined Products

High Precision Machined Assemblies

High Precision Machined Component

The Precision Component Needs To Be Assembled Well To Keep Them Functioning!

The modernized world is prone to mechanical elements, and industries are completely based on using and utilizing different components. Additionally, precision machines must be assembled properly to keep them functional for longer. In the manufacturing industry, “high precision machining” refers to machining domains with forbearances in a particular span.

At the same time, another precision known as “ultraprecision” has tolerances in the sub-micron range. Machining parts with very tight tolerances are always a challenge; however, the sophistication of a job is defined not only by mandated tolerances but also by the materials used and the number of segments involved in it.

High-precision machining is required in all industries. We are leading manufacturers and exporters of all varieties of cement, power, petrochemicals, and steel applications. However, we’ve witnessed a greater push toward higher precision work in all enterprises.

Precision machining is a manufacturing technique that uses computer-controlled appliance mechanisms for parts production. It is a high-velocity machining process to make parts demanding high complexity, tight tolerances, or both. Precision machining may be done by a proficient precision technician operator or even advanced robots. All these technical works need to be compact to provide smooth function. The High Precision Machined Assemblies are the need of the hour to make the task flow smoothly and efficiently.

Precision Machine And Its Assembly!

An assembly machine is a component of equipment built to assist an exhibit employee with finalizing a task. Common applications for assembly machinery include bolt torquing, screwdriver, part cutting & trimming, clip, installation, labeling & marking, testing & inspection, together and packaging & sorting, and pressing or fusing parts.

3 Types Of Assembling Options!

1. Ultrasonic Welding

2. Gluing

3. Laser Welding

Need To Assemble The Precision Machine!

Industries are prone to disasters and destruction due to the wrong method of utilization, which creates hazardous situations for the people and industry. There should be a proper arrangement of technical components, so it doesn’t hinder the enterprise. To concentrate on it, we need to have the proper assembly of the machine, and they provide the following benefits :-

Smooth Work

Time-Saving

Less Wastage

Resistance

Lowering Cost

Where To Get The Manufacturer To Help With Precision Assembly ?

Imperial World Trade Pvt. Ltd. is the leading exporter and manufacturer of precision machining and assembling components. It has a high variety of products that can help accomplish your demands. We have a great availability of precision assemblies and deal with PEKO, which specializes in manufacturing intricate parts for precision assemblies; with that, it has a substantial force for the redundant build of tight tolerance and convoluted quality parts for precision assemblies. Get connected to us for budget-friendly precision assemblies.