Forged Components

Mild Steel Forged Components

Mild Steel Forged Components

What are the benefits of using our SS Forged Components?

Stainless steel forging is a process for industrial manufacturing. It is an open-die procedure due to heat resistance, corrosion resistance, and excellent strength. For sanitary applications, we at Imperial World Trade Pvt. Ltd. Use the alloy of stainless steel as it is the most common austenitic stainless steel and has the properties like corrosion resistance and easy cleaning.

In the health industry, engineering, transporting, mining, construction, and manufacturing, we use these types of SS Forged Components. Stainless steel is a versatile alloy suitable for different industrial applications. We use stainless steel because it has very good corrosion and heat resistance and is as strong as ant carbon steel.

Advantages of SS Components

Advantages of using our SS Forged Components in industries

Heat and corrosion resistance are some of the main advantages of using stainless steel. And by forging this stainless steel, we can enhance the durability and strength of the stainless steel to use in very difficult and harsh environments. These are the best and ideal materials.

By forging to the stainless steel, we create much stronger parts like any other process like casting and machining. Because of this, we can increase the strength of the steel as it shapes the workpiece and grain flow. Let’s have a look at different types of stainless steel grades.

Duplex

Precipitation hardening

Martensitic

Austenitic

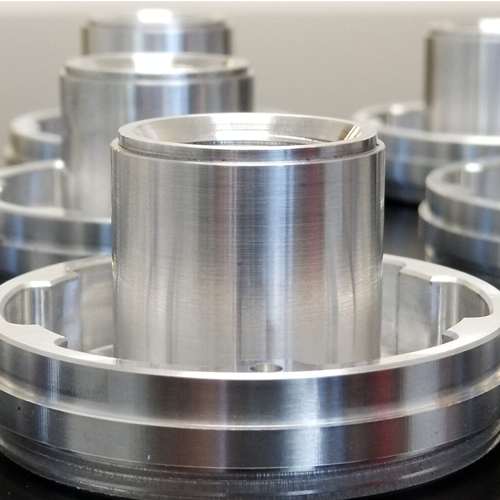

Forged SS Components

The common application of our forged SS components

We supply our forged component of stainless steel for making various industrial equipment and normal regular-use things, as these are much stronger than any other material and have more resistance power from corrosion. Some examples of different industries like:

Marine

Medical tools

Gearbox

Aerospace

Rail industries

Oil

Recreation and sports

Different hand tools

On top of that, these are some additional application of our SS Forged Components, which includes:

- Wheel hubs

- Pinions

- Spindles

- Sprockets

- Levers

- Gears

- Brackets

And we have different products like valve bodies, refrigeration components, golf club equipment of stainless steel, rail components, gun components, gear blanks, and different kinds of fittings.

Forging any stainless steel will inherit all the benefits of the alloy. We can increase the thermal performance of any other stainless steel component by redirecting and maintaining the internal flow of the grains. Due to these properties, we use these alloys for making the product, like heat exchangers and furnaces, which are used for high-temperature use. Because of the thin layer of oxide on the steel surface, it has inherent resistance from corrosion in general. So we used to make different electrochemically affected products by doing ss forging.