Casting Products & Parts

Ductile Iron & Cast Iron Casting

Ductile Iron & Cast Iron Casting

You should know everything about Ductile Iron Casting And Cast Iron Casting Parts!

In our day-to-day life, we often use various materials and metals to make our workflow easy and fast, but there are the use different methods and types that we need to learn. Iron is one of the most used metals in today’s world. Every industrial and manufacturing sector requires the involvement of iron to enhance their productivity. Manufacturing processes use different methods to produce solid metal pieces called castings. The procedure consists of molten metal pouring into a mold, letting it cool and solidifies and takes shape and structure of the molding cavity.

Casting offers remarkable liberation in constructing intricate components. It is also facilitative to high-volume production runs, where material quantities can be efficiently managed to minimize waste and lower costs. The process of casting is also called founding.

Casting Components

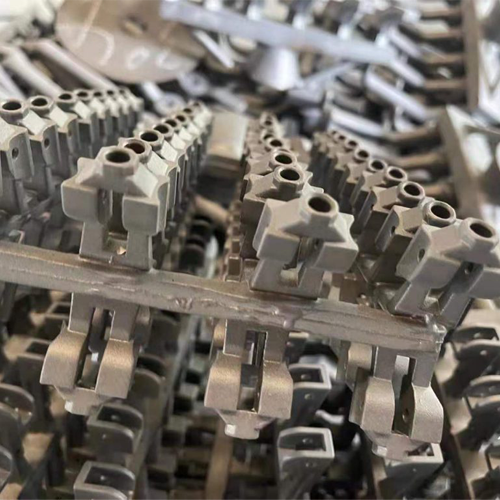

Ductile Iron Casting!

Ductile iron, also known as nodular iron or spheroidal graphite iron is very similar to gray iron in arrangement, but during solidification, the graphite nucleates as globular particles in ductile iron rather than as flakes. Ductile iron is not a single component but part of a cluster of materials that can be produced with a wide range of possessions by restraining their microstructure. Relying on heat treatment, these particles’ phase of the matrix is ferrite. Ductile iron is more powerful and more shock resistant than gray iron. Although it is more expensive due to alloys, it may be the preferred economical option because a lighter casting can perform an equal function.

Benefits

Resistance

Light Weight

Minimum Brittle

Economical

Casting Components

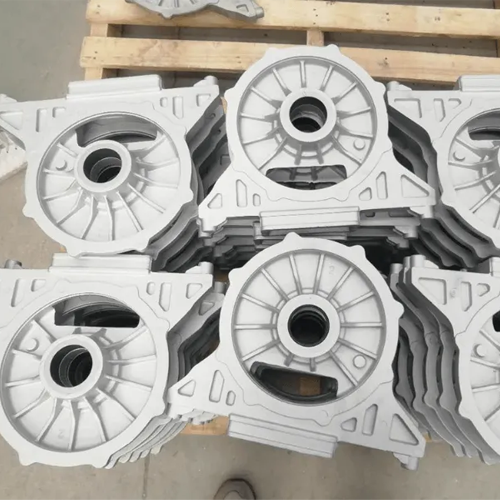

Cast Iron Casting!

Cast iron castings are the metalworking action generally seen in metal foundry manufacturers. Its methods possess melting cast iron material, filling the molten fluid to the mold, and forming the casting parts. Iron casting has a long tradition dating back to history, and cast iron castings greatly contribute to various life applications. We can see many Cast Iron Casting Parts coming from casting cast iron foundry manufacturers and factories. An iron casting is a hard product obtained from combining iron with carbon. This can be readily cast in a mold and contains more carbon than steel. Casting is often used for making shapes that would be difficult or uneconomical to make using other production methods.

Benefits

Strength

Fluidity

Low Maintenance

Conclusion

At Imperial World Trade Pvt. Ltd, you can get it at a more budget-friendly rate with premium quality. We are the leading manufacturer and exporter; with an experienced and skilled team, we can help you get the best product and services to meet your casting requirement.