Casting Products & Parts

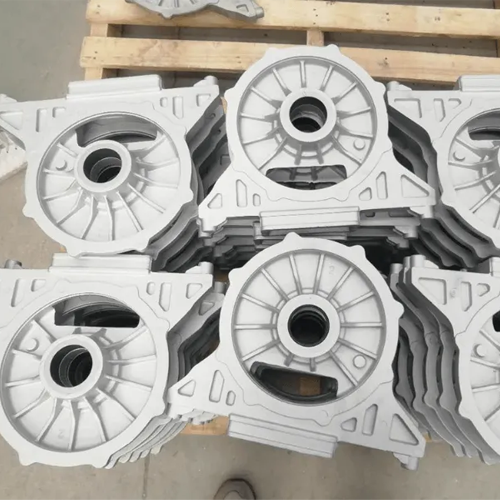

Aluminum Gravity Casting

Gravity Casting

Aluminum Casting Parts!

Aluminum is the third most generous component in the world and the most abundant metal in the earth’s crust. Aluminum contributes to the earth’s core mass. However, refining is challenging compared to other metals, such as iron. For this reason, aluminum has crept behind other metal products, while efficient and cost-effective methods were developed to overcome this sophistication.

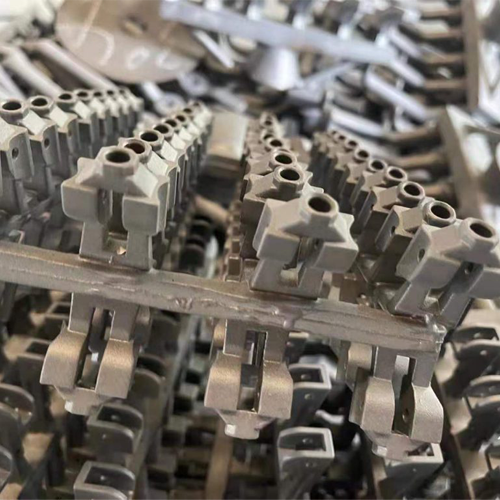

Aluminum casting produces high forbearance and high-quality parts by pouring molten aluminum into a specifically designed, precision-engineered mold or Cavity. It is an efficient process for producing complex, detailed parts that fit the original design’s specifications.

The typical method for casting aluminum is to pour molten aluminum into a steel mold that has been accurately processed to ensure that the cast piece will have an extremely smooth and refined surface. This process is one of several strategies used to produce Aluminum Casting Parts, each used to create specific types of components.

Casting Aluminum Parts

Tips For Casting Aluminum Parts!

Selection Of Material

Machining

Shrinkage

Thickness

Strength

Assembly

Designing

Reasons To Choose Aluminum For Casting Parts!

Weight

Ductile

Strength

Conduction

Resistance

Conclusion

Suppose you are looking for forged or Aluminum Casting Parts and components, Imperial World Trade Pvt. Ltd will be the place that has the expertise to deliver high-quality products for various sectors. Get connected to us and receive great customer experience value at a budget-friendly rate.