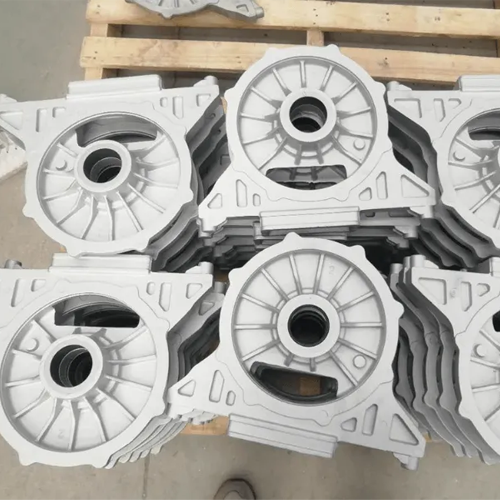

Casting Products & Parts

Manganese Steel Casting

Manganese Casting

How Are Manganese Steel Castings Important?

Manganese steel castings are specialized steel used for highly resistant parts, such as components for heavy construction, mining, and agricultural equipment. Not only is this material incredibly hard and resistant to wear due to its high manganese content, but it can also quickly absorb energy from redundant blows without failure. It makes it ideal for demanding applications in harsh environments. Manganese steel castingscan be developed with explicit forbearances and an excellent surface finish. Yet, they retain their high potency over the long service life; less maintenance or replacement is necessary.Eventually, this makes them an immaculate choice whenever foremost toughness or strength is combined with wear resistance is needed.

Manganese Casting

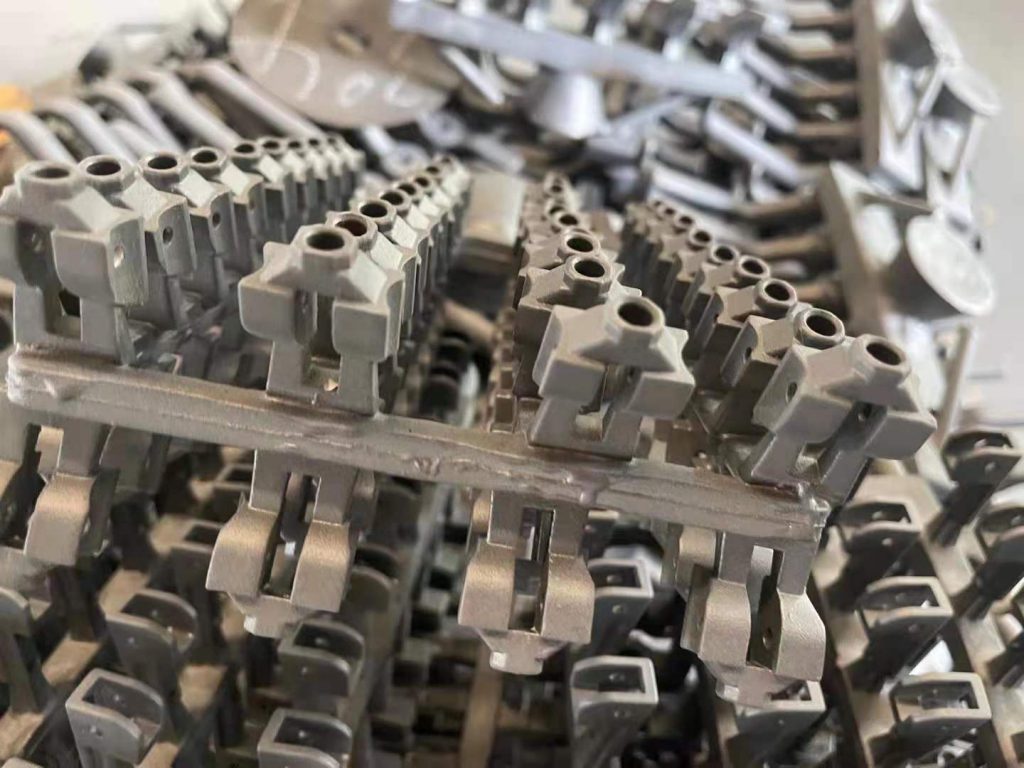

Process Of Manganese Steel Casting

1. MoldDevelopment

2. Modeling

3. Melting

4. Metal Pouring

5. Clean And Heat Treatment

6. Machining

7. Inspection

Benefits

There are usually many benefits of manganese steel casting, but here are the top five benefits we must consider in casting it.

Durability

Cost-effective

Quality

Usability

Noncorrosive

Conclusion

The use and need for manganese steel casting have enormously increased. Imperial World Trade Pvt. Ltd produces strong and durable parts at an affordable price. Only some materials can contend with manganese steel castings, as it has superior power and durability compared to other alloys used in the casting process; its cost-effective production methods can be the best choice due to its easy machining and forming capabilities. Get connected today with us to avail the best product.